B&Plus production system

Have a various plants and product lines

in order to offer high quality products.

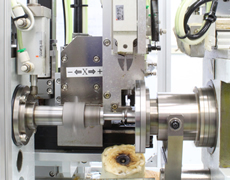

(1)Special coil winding machine for various size and figure

The coil which is one of the important parts in manufacturing a wireless Power supply technology. We installed an exclusive automatic coil winding machine to use the coil of high quality for our product. Having high precision and empty core winding are possible and lead to the mass production of high quality.

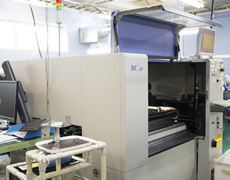

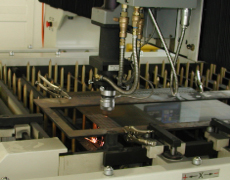

(2)Own chip mounter for high quality and small pieces manufacturing

Since the board is electronic parts, it is impossible to separate it. It correspond to small parts, and the board production line supports to perform the stable and speedy production.

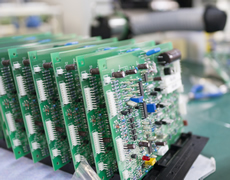

(3)Assembly line for various kinds kinds and small production

We offer various wireless Power Supply products and establishes the system which we can produce from a single product. Always seeking for improvement and preparing to offer the product as quick as we can.

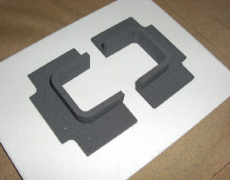

(4) Various processing equipment

Core processing machine

In order to verify the ferrite core dedicated to product realization, part of the ferrite core at the prototype development stage is created internally.

Main process is to press the powdered ferrite core into a mold then press it and mold it to the required shape with special machine.

In the end bake in a sintering furnace set at 1500 ℃.

Machining

In recent years, the product shape required by customers has become complicated and high processing accuracy is required. We also use three axis machining centers to challenge various processing technologies to meet customer's request.

(5) Mass production

In addition to the lines specialized for multi-product and small-volume production with reduced set-up time, we have also built a line construction specialized for mass production. We have built a manufacturing process that can accommodate customers' large orders.

We are constantly trying to make improvement of our work. Improvement of single assembly of each work. Introduction of jigs and tools with new ideas is also under construction now.

(6)Subcontracting network

We have an outsourcing network that can respond flexibly to various cases.

We can outsource mass production development products and focus on high added value by internal development and production of small quantity lot and special structural products.

For example, we asked the boards from design to procurement and completion of parts to two companies.As for the prototype board and the mass production board, the subcontractor is selected according to the situation.

Efficiently cooperates with subcontractors while responding to everyday production, including resin forming, parts processing related and harness related.