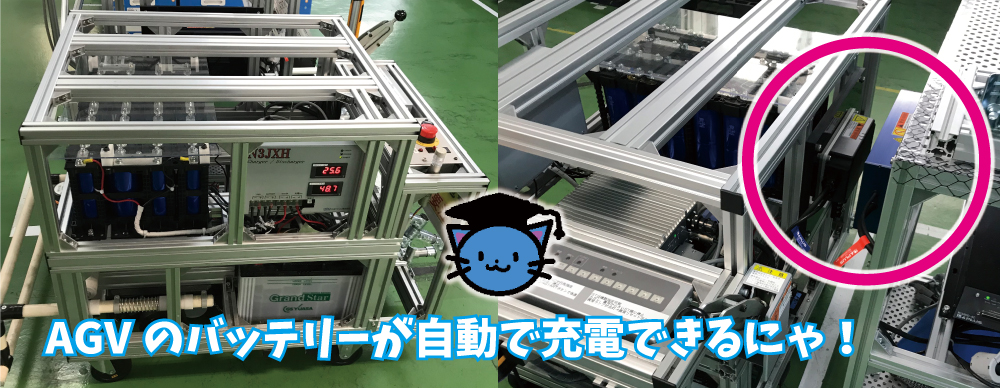

[Case study] 600W wireless charging was adopted for AGV of Chemicon Nagaoka Co., Ltd.

Overview of Chemi-con Nagaoka Co.,Ltd.

Chemi-Con Nagaoka modularizes the electric double layer capacitors produced by the Nippon Chemi-Con Group for the purpose of saving energy and reducing the environmental load, and produces them for a wide range of applications such as in-vehicle applications, backup power supplies and energy-saving equipment.

In addition, it's a manufacturer that manufactures camera modules that achieve high image quality and miniaturization, such as drive recorders, code authentication, and sensing.

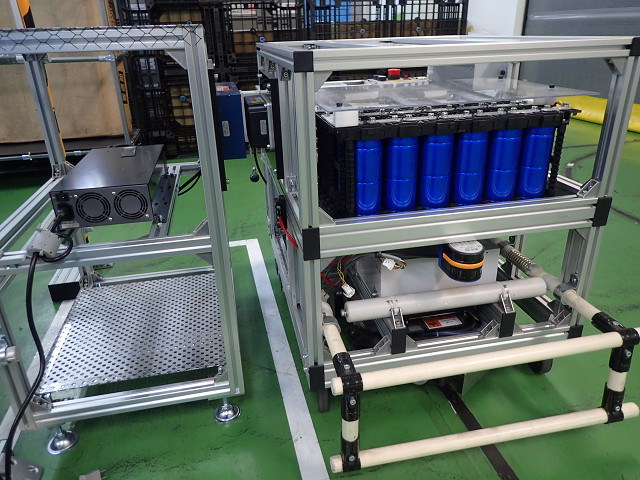

They are developing a new business with a view to providing solutions, and this time we have adopted it for charging our own electric double layer capacitors installed in AGVs.

[Q1]

Please tell us about the features of the AGV that supplies power from the electric double layer capacitor of Chemi-con Nagaoka.

[A1]

Electric double layer capacitors have a smaller storage capacity than batteries and are not suitable for continuous operation for a long time.I thought I can make use of it.

First, since the internal resistance is smaller and the loss during charging and discharging is smaller than that of a battery, it can be charged with a large current, which means that it can be charged in a short time during stop or standby.

Secondly, it has a long life, and even if it is repeatedly charged and discharged, it does not need to be replaced for more than 10 years. I think it's almost maintenance-free compared to the battery life.

[Q2]

Please tell us how you adopted the 600W wireless charging system of B&PLUS.

【A2】

There are two main reasons for adoption.

First, a small wireless charging system was needed to miniaturize the AGV. The kW class wireless charging system has already been adopted, but considering the mileage and charging timing, it has become a device that exceeds the specifications. We are developing AMR in the future and are considering using it for whirligig beetles between processes, but because we want to run in a narrow space, we found a wireless charging system from B & PLUS while searching for a small one.

The second reason for adopting this is that B & PLUS conducted a charging simulation when using electric double layer capacitors. It was also helpful that I had a plan to use it in advance.

[Q3]

How is it adopted ?

[A3]

Unlike batteries, electric double layer capacitors fluctuate in voltage in proportion to the storage capacity, so the charging unit is configured with a DC / DC converter to charge and discharge the electric double layer capacitor, and operates without problems. Since it is charged and discharged frequently, it is wasteful to rely on manual labor for charging, and even if it is automatic, if it is a contact type, it will accelerate the deterioration of the contacts, so it is frequent to use an electric double layer capacitor. I think that wireless charging is suitable for systems that repeatedly charge and discharge.

[If you would like to know more information about Nippon Chemi-Con Co., Ltd., please contact the link below]

Category

- お知らせ (395)

- 製品ニュース (217)

- 営業のおすすめ! (119)

- 導入事例 (100)

- ワイヤレス新技術 (95)

- AGV充電関連 (66)

- News(En) (50)

- アプリケーション (41)

- Novotechnik関連 (34)

- Application(En) (34)

- 導入事例 AGV関連 (24)

- AGV(En) (16)

- IDシステム (13)

- WPT(En) (11)

- ID(En) (5)

Tags

- ワイヤレス給電&信号伝送システム (127)

- 新技術 (103)

- ワイヤレス充電 (94)

- AGV (72)

- 営業のおすすめ (72)

- IDシステム (50)

- 移動 (46)

- 搬送ライン (40)

- 回転 (38)

- ロボット (38)

- 識別管理 (37)

- その他生産現場 (35)

- 着脱 (33)

- 自動車 (32)

- 展示会情報 (31)

- recommend (30)

- B&PLUSの紹介 (30)

- Automotive factory (27)

- カスタム (20)

- 自由研究 (16)